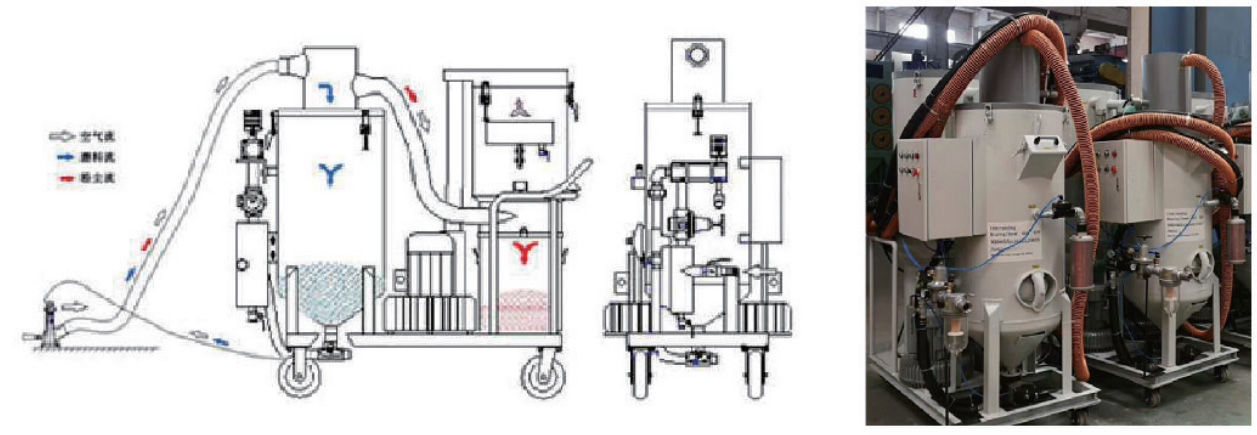

Automatic recycling mobile sandblasting machine

Performance Characteristics

Automatic recovery type sandblasting machine is a kind of environmental protection sandblasting equipment, can realize heavy multi-purpose and efficient online mobile sandblasting operation, according to the different negative pressure generation device, divided into electric and pneumatic two models; This equipment adopts compressed air power, high-speed abrasive jet to the workpiece surface, clean the workpiece surface treatment after the impact of the abrasive, the surface reaches a certain cleanness and roughness, again through the vacuum pump to produce negative pressure, recycle of sand and dust, and through the sand dust separation system of the equipment will continue to recycle, complete separation of abrasive dust into the dust collection box, Under the control of a single switch, the equipment sandblasting, sand return, dust separation, sand recycling, dust filtration and other actions are automatically completed, the working environment is clean and pollution-free, the working site meets the "GB103328-10333-89" workshop air dust health standard. HC series sandblasting machine is devel-oped and evolved on the basis of introducing and absorbing the sandblasting technology of japan hsu subway co., ltd., and is constantly perfected according to the market demand. Standard design, stable and reliable work, high processing efficiency.

Scope Of Application

At present, this equipment is widely used in petrochemical industry, metal structure, ship building, pipeline power, aerospace, locomotive manufacturing and other industries. It is an ideal equipment for pretreatment of various steel structures before painting.

Standard Parameter Table

|

Model |

150L |

300LA |

300LB |

300LC |

|

Working pressure |

4-7bar |

4-7bar |

4-7bar |

2-7bar |

|

Supply voltage |

380V;50Hz |

380V;50Hz |

380V;50Hz |

380V;50Hz |

|

Power supply power |

4KW |

5.SKW |

8KW |

11KW |

|

Gas consumption |

1.5-3m3/ min |

2-3m3/min |

3-6m3/min |

6.2m3/min |

|

Working radius |

20m |

20m |

40m |

60m |

|

Abrasive rate |

G25-150 |

G25-150 |

G25-150 |

G25-150 |

|

Abrasives types |

Steel grit, brown corundum, white corundum, etc |

Steel grit, brown corundum, white corundum, etc |

Steel grit, brown corundum, white corundum, etc |

Steel grit, brown corundum, white corundum, etc |

|

Tsk mouth diameter |

6mm |

8mm |

8mm |

10mm |

|

Surface cleanliness |

Sa2.5-3(GB8923-88) |

Sa2.5-3(GB8923-88) |

Sa2.5-3(GB8923-88) |

Sa2.5-3(GB8923-88) |

|

Surface roughness |

40-70um(GB1031-83) |

40-70um(GB1031-83) |

40-70um(GB1031-83) |

40-70um(GB1031-83) |

|

Work efficiency |

6-8m2/hour |

8-12m2/hour |

8-12m2/hour |

12-15m2/hour |

|

Control mode |

Electronic Control DC24v |

Electronic Control DC24v |

Electronic Control DC24v |

Electronic Control DC24v |

|

Filtering method |

Imported filter cartridge filtration |

Imported filter cartridge filtration |

Imported filter cartridge filtration |

Imported filter cartridge filtration |

|

Filter element filtration area |

18m2 |

28m2 |

28m2 |

28m2 |

|

Machine weight |

400kg |

500kg |

500kg |

3000kg |

|

External dimensions |

1800*980*1840(L*W*H) |

2000*980*2240(L*W*H) |

2000*980*2240(L*W* H) |

2160*1450*2620 (L*W*H) |

Prototype Display