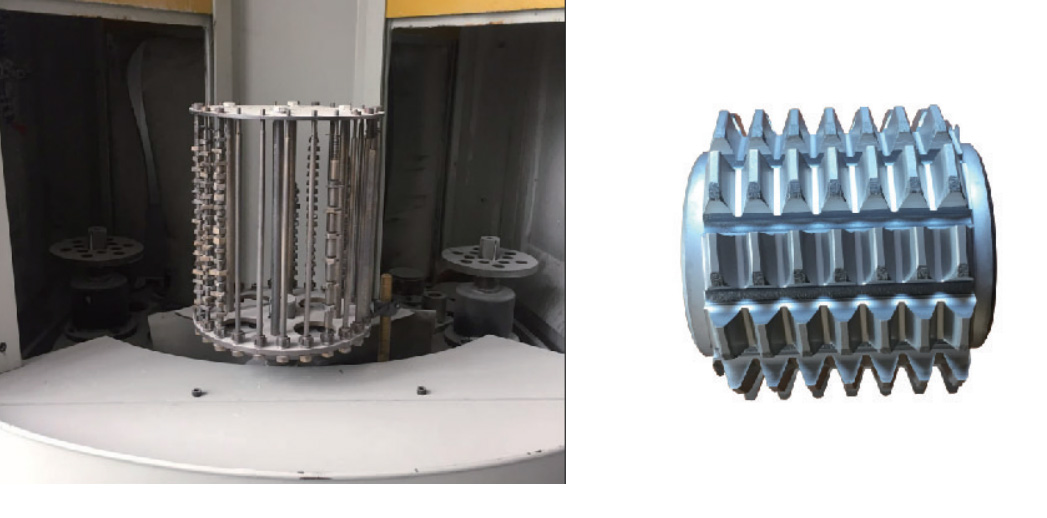

Sand blasting equipment for dry cutting tools

Performance Characteristics

Equipment Introduction:

1. Introduction to the Process of Special Sandblasting Machine for Surface Passivation and Cleaning of Cutting Tools

2. Sandblasting is professionally applied to the passivation sandblasting and finishing of hard alloy cutting tool blade coatings. The passivation technology of hard alloy cutting tool blade edges is not yet widely valued, but it is a very important issue. The reason why it is important is that the passivated tool can effectively improve the edge strength, extend the tool life, and enhance the stability of the cutting process. The main factors affecting the true cutting performance and tool life of a tool, in addition to tool material, tool geometric parameters, tool structure, and optimization of cutting parameters, have been realized through extensive practice of tool edge passivation: having a good edge shape and edge passivation quality is also a prerequisite for whether the tool can perform cutting processing quickly, efficiently, and cost effectively.

3. Why do we need to perform blade passivation treatment

1) The cutting edge of the tool after grinding with ordinary grinding wheel or diamond grinding wheel does indeed have varying degrees of micro notches (i.e. small chipping and sawing). The former can be observed with the naked eye and a regular magnifying glass, while the latter can be observed with a 100x (with 0.010mm engraved lines) microscope, with microscopic notches generally ranging from 0.01-0.05mm, and in severe cases up to 0.1mm or more. During the cutting process, the micro notch at the cutting edge of the tool is prone to expand, accelerating tool wear and damage.

2) Modern high-speed cutting and automated machine tools have put forward higher requirements for tool performance and stability, especially for CVD coated tools or blades. Before coating, the tool edge is almost invariably passivated, which is necessary for the coating process to ensure the firmness and service life of the coating.

3) The cutting edges of CNC machine tools and production lines imported from abroad have been completely passivated. Numerous pieces of information indicate that tool edge passivation can effectively extend tool life by 200% or more, greatly reducing tool costs and bringing enormous economic benefits to users.

Detail Display

Prototype Display

-

lAST ONE:Pipe polishing machine